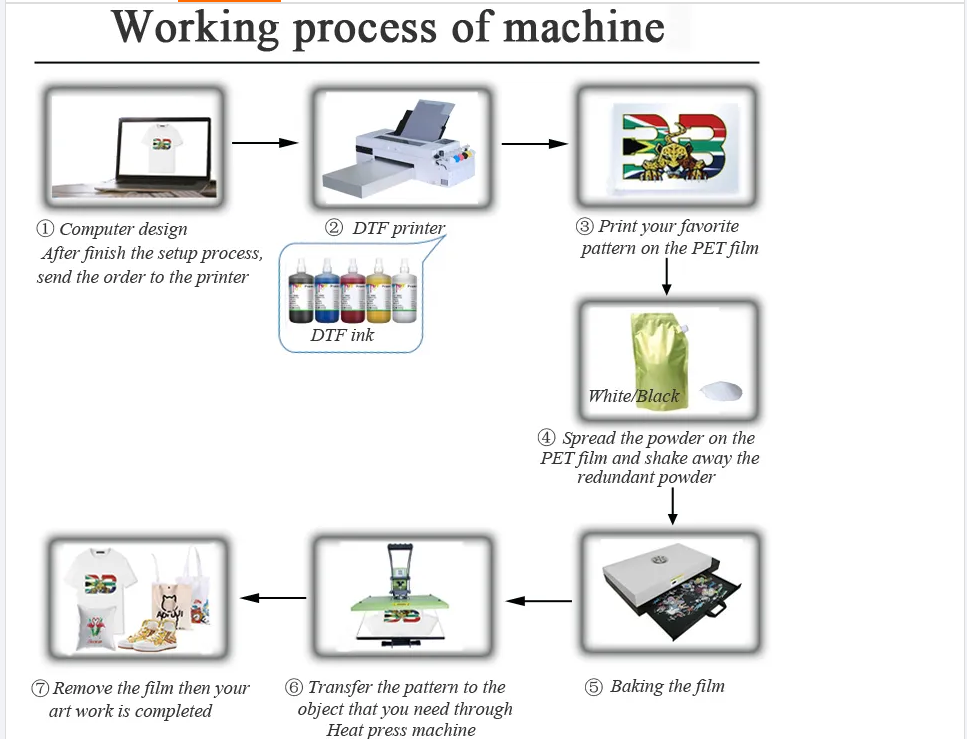

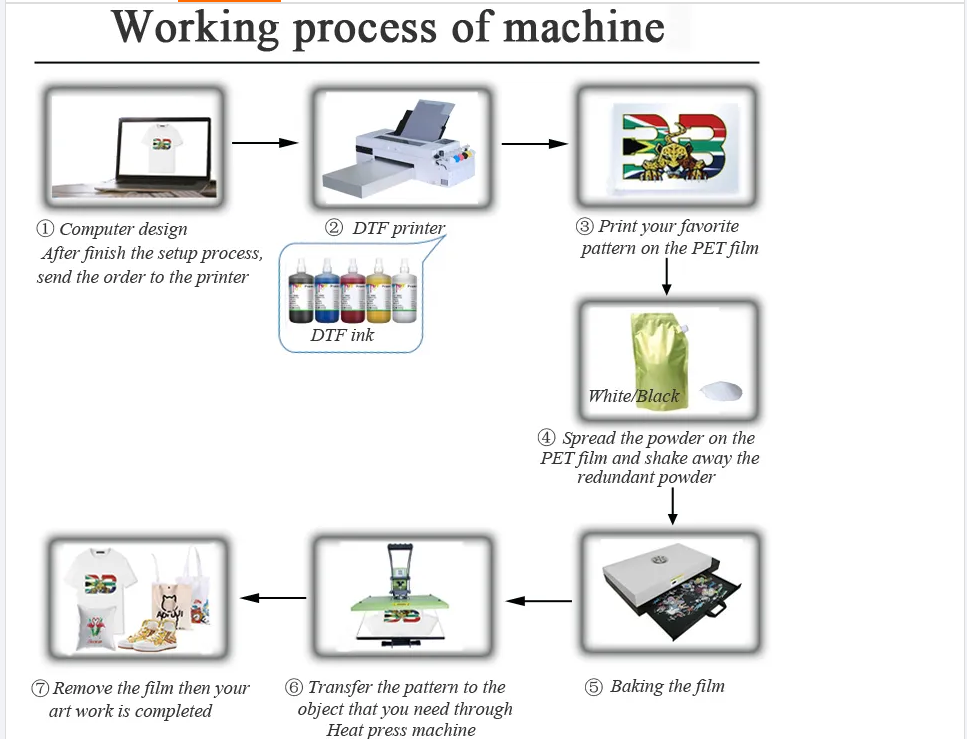

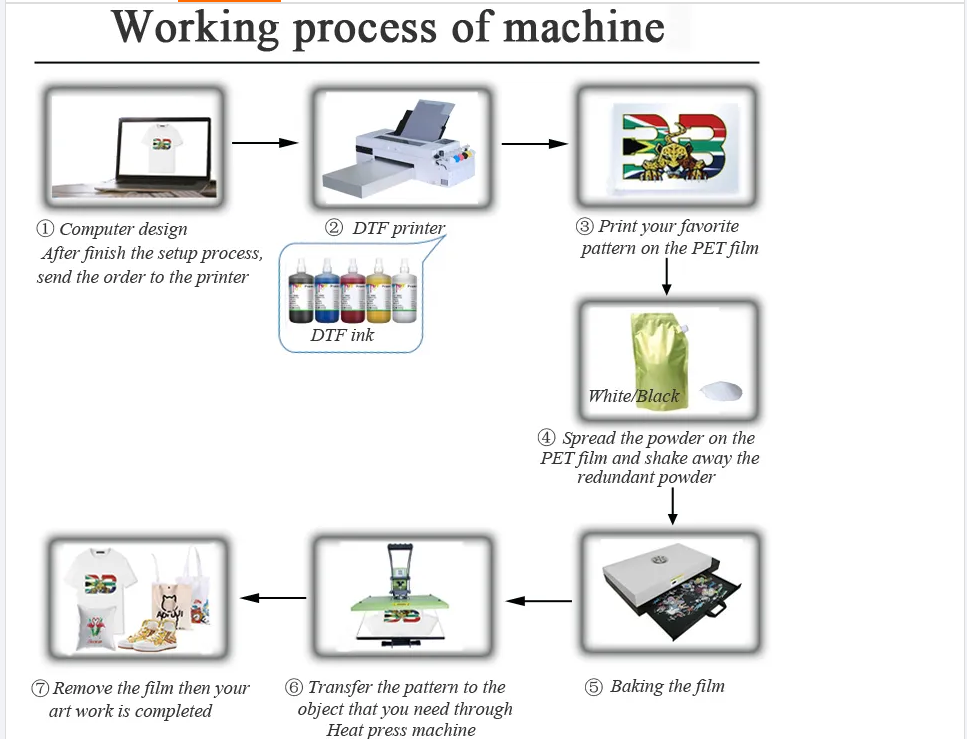

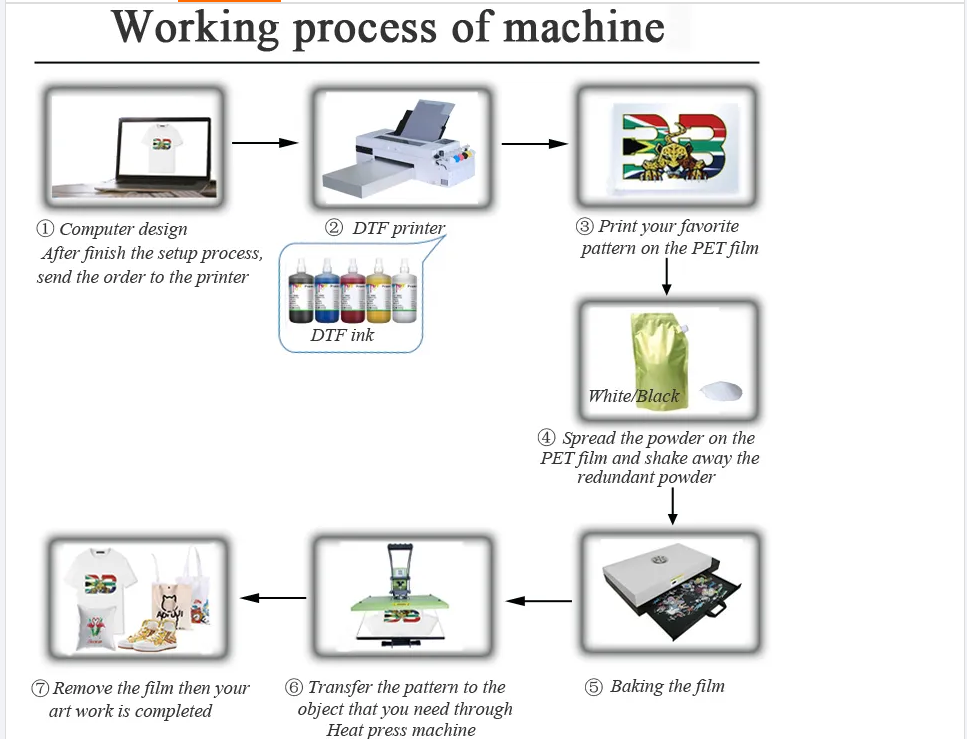

Step 1: Print on the Film

Insert the PET film in the printer trays.

Hit Print.

The inkjet printer will print “direct to film”, transferring the image onto your PET film.

Be careful not to smudge the print when you remove it from the tray!

Step 2: Spread the Powder

This step is the application of hot-melt powder on the film that has the printed image on it.

You have to apply the powder while the print is still wet!

Make sure and spread the powder evenly.

Normally you would keep a tray next to the printer, sprinkle the power onto the web print, then seasaw back and forth until it covers the wet ink. Then CAREFULLY shake off the excess.

Alternately, one can use automated shakers available for busier custom t-shirt shops.

Step 3: Melt the Powder

Just like the description indicates, your next step is to actually melt the powder in place.

The most common way to do this is just to put the direct to film DTF transfer in an oven for about 2 minutes.

Alternatively, if you’re already in the custom t-shirt business doing DTG or vinyl or white toner printer transfers you can use your heat press. Just make sure you are hovering and not applying any pressure. Or that the top of the press isn’t in contact with the transfer at all.

There are no times and temperatures for curing DTF transfers here on purpose. It’s always best to check with the manufacturer!

Step 4: Pre-Pressing the T-Shirt

It doesn’t have to be a t-shirt of course. But whatever you’re going to apply your DTF transfer to should be completely smooth. Any wrinkles will show up in the print!

And maybe even more importantly it will completely dry the material. You’d be surprised how much moisture fabric can absorb from humidity in the air, and that would affect print quality.